|

|

|

|

|

|

|

|

|

|

|

|

| |

|

CHAINS

FROM RENOLD CHAINS

FROM RENOLD |

| |

| Oilfield

Chains |

|

|

| Key Features: |

| • |

Close control of

material specifications to ensure consistent response to heat

treatment |

| |

| • |

Renold’s new improved

plate profile ensures optimum stress distribution for greater

reliability |

| |

| • |

Fatigue life is enhanced by

shot peening and other pre-stressing processes on plates, bushes

and rollers |

| |

| • |

Renold’s special holing

processes for oilfield chain were specifically developed to

give improved fatigue resistance while minimizing susceptibility

to stress corrosion cracking. |

| |

| • |

Bearing pins undergo customized

heat treatment and surface finish operations to ensure unsurpassed

toughness and wear life |

| |

| • |

Closely controlled tolerances

ensure smooth robust running even at high speeds. |

| |

| • |

Specially formulated factory

lubrication gives substantially better initial wear performance

and enhanced corrosion resistance. |

| |

| • |

Detachable chains for ease of

fitting and replacement |

|

| • |

All chains are proof loaded

before packing in durable containers |

|

| • |

Roll pins standard for extra security |

|

|

|

|

|

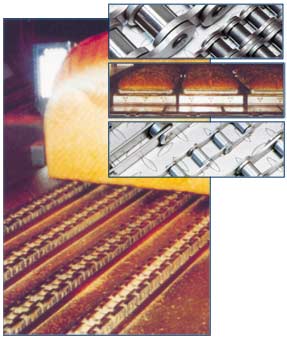

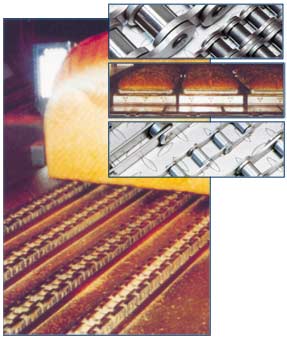

| Cement

Chains |

|

|

| Key Features: |

| • |

All Renold chains

manufacturing and assembly processes are monitored by Statistical

process control in conformance with ISO 9000 Quality systems |

| |

| • |

Consistent overall tolerances

make it ideal for conveying systems requiring precise alignment

on multi-strand chain layout. |

| |

| • |

Maximum chain strength and resistance

to wear are achieved by strict control of the material specification,

and by using state of the art heat treatment processes |

| |

| • |

Special materials selected for

the unique combination of demands from the cement industries. |

| |

| • |

Fatigue life is improved by

maintaining precise fits and tolerances between the pins, bushes

and side plates |

| |

| • |

Chain and sprocket life are

optimized by the rigid control of pitch accuracy, resulting

in excellent gearing, lower friction and reduced wear. |

| |

| • |

Bush and roller life are maximized

by controlling the concentricity of these components and careful

selection and control of the heat treatment process |

| |

| • |

Breaking loads exceed the minimum

international standards, and chains are able to be supplied

with breaking loads up to a maximum of 5000kN |

| |

| • |

Strict control of inner and

outer plate clearance ensures effective lubricant penetration.

Renold’s use of specially formulated lubricants provides

maximum protection and thus minimum wear |

| |

| • |

Installation and maintenance

guides available. |

|

|

|

|

|

|

|

| Bakery

Chains |

|

|

| Key Features: |

| • |

Correct chain selection is essential

for optimum performance. Renold’s experienced sales, production

and design staff are always available to advise on particular

products and applications |

| • |

Close control of material tolerances

ensures excellent resistance to high shock loads |

| • |

The performance of Renold conveyor

chain is ensured by a programmed of continuous testing and quality

control of component dimensions, fits and material properties |

| |

| • |

Breaking loads exceed the minimum

international standards |

| |

| • |

Close control of material specifications

to ensure consistent response to heat treatment |

| |

| • |

Unparallel pitch accuracy ensures

smooth operation and low noise |

| |

|

|

| Theme

Park Chains |

|

|

| Key Features: |

| • |

Rugged, robust design to maximize

durability |

| • |

Special heat treatment and

stress reducing process maximize resistance to shock loading |

| • |

Attachment fitting

is varied to match load specification. |

| • |

Optimum zinc coating thickness

for corrosion protection |

| |

| • |

Special

water repelling grease to ensure smooth running |

|

| • |

Bespoke design service available

as required |

| • |

Renold Theme Park installation,

maintenance and safety manual is available a must for all installers

and maintainers of chain |

|

|

|

|

| Designed by |

|

|